CARBON COMPOSITE END EFFECTORS

What is a carbon fiber end effector?

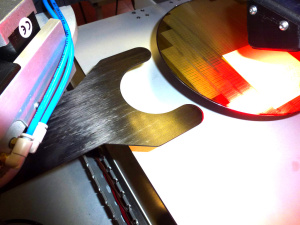

The end effector (EE) is the part of a handling system which is in direct contact with wafer. Its role is crucial to assure a good, safe and reliable handling.

If the end effector fails, even the best handling system will not give the best performances and can damage wafers.

Our carbon composite end effectors have been perfected during years of experience to fulfill the needs of a safe and effective wafer handling together with the highest possible reliability.

Why carbon fiber?

Carbon fiber is a very though material, which will not break or permanently bend under stress, so extremely durable and then reliable.

Carbon composite has also a surface which is not subject to scratch wafer surface in normal conditions, and can be used for a lot of applications in wafer handling.

How much does it cost?

Duration means a very low cost of ownership due to the part, since a durable part will not need to stop the process for replacement and will not give damages to wafers due to its breakage.

Our parts can be either used by OEMs for new equipment or as spare parts for existing machines and can be applied to the majority of handling systems.

How can you have it?

We offer to all our customers a rapid prototyping service. Starting from a drawing or a sample we can produce a compatible part in a very short period.

Carbon sheet is manufactured according to the application needs, and then CNC milled. All the parts are controlled with a 100% sampling during all the process to assure the best final quality.

Carbon sheet is manufactured according to the application needs, and then CNC milled. All the parts are controlled with a 100% sampling during all the process to assure the best final quality.

See below for a list of our end effectors and technical documentation